What is the process of aluminum die casting?

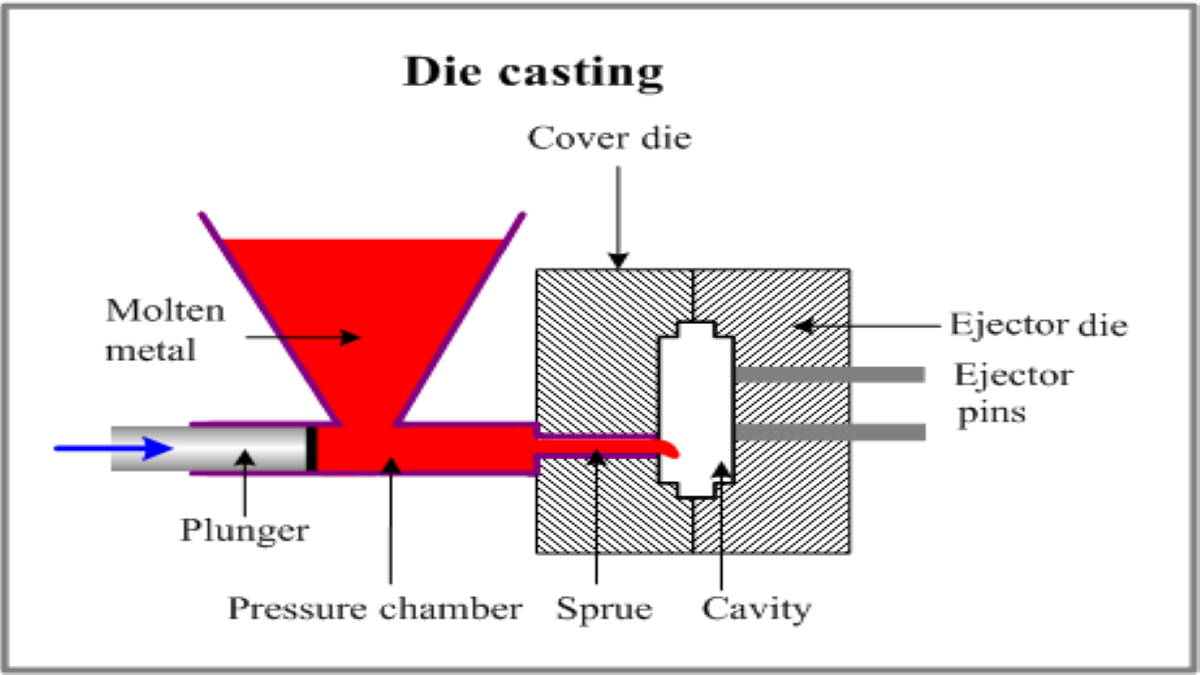

An aluminum bar is heated until it is completely melted at a high temperature and is then pressed into a cavity that has already been pre-shaped in the mold to create the desired metal item. This manufacturing process is known as die casting.

In the cold chamber of the casting machine, aluminum is melted in a similar manner to the hot chamber procedure. This is necessary because the injection mechanism in a hot chamber machine would be harmed by the high temperature of the molten aluminum.

The melting pot and the die are separated by cold chamber machines, which then fill the die with molten aluminum alloys under intense pressure. After injection, the aluminum takes some time to solidify. You must split the mold’s two pieces apart to reveal the aluminum cast component.

Most of the time, the finished products don’t require major machining and can be delivered quickly. Additionally, die-cast molds can be reused to create the same components before they degrade.

Therefore, aluminum die-casting is an ideal manufacturing process for manufacturing large volumes of aluminum. Because of this, aluminum die-casting has gained popularity in many industries and Aluminum Parts Manufacturer prefer to die-cast aluminum for large volumes of production.

Advantages of Aluminum Die-Casting

A variety of surface finish options and dimensional stability are available with die casting aluminum. They are also adaptable and can be used in almost any business.

The following are a few advantages of casting aluminum:

- Tensile strength is good

- Surface finishes that are excellent

- Impurities and porosity are reduced

- Raw materials with low costs

- Precision in thickness (less than 1.5 thickness is achievable)

- Molecular structure ensures dimensional tolerance without microcracks

- Longevity

- Pressure and airtightness

- Complex parts can be produced

- Chemical and mechanical properties of many alloys to choose from

Create Aluminum Die Casting Parts: Three Things to Keep in Mind

Manufacturers must take certain safety measures when casting aluminium.

Mold Design

The first big thing is the mold design. The mold needs to be efficient so that melted aluminum can be injected and built parts can be produced effortlessly. A parting line (the line that separates two halves of each mold) should be considered by the designer before finalizing the plan.

Wall Thickness

You should also take the pieces’ wall thickness into account. With automation technology and sophisticated machines, there is no minimum thickness level. To achieve better outcomes, it is best to select a consistent thickness.

The Location of Injection Point

The location of the injection point is the next thing you should think about. If there is a danger that the molten aluminum won’t reach every nook and cranny of the die, more injection points may be added. It also helps to create cavities.

HULK Metal – Your Cost-Effective Aluminum Die Casting Service Supplier

Since the turn of the century, HULK METAL has offered aluminum die casting services. Over time, the company has integrated the supply chain to boost service capabilities and service content. The business can currently make aluminum die castings from a variety of alloys, including Al-Mg, Al-Zn, Al-Si, and Al-Cu. Leading die-casting business HULK Metal has served a variety of industries, including those that manufacture machinery, automobiles, motorcycles, bicycles, home appliances, construction, power, and heat dissipation, with top-notch die-casting services.

You can rely on us to have engineers, strategists, and creative professionals to finish your project exactly how you want. We provide the greatest services at a competitive price, from prototyping to mass production.

In our workshops, automated devices and robots created using cutting-edge technology are utilized.