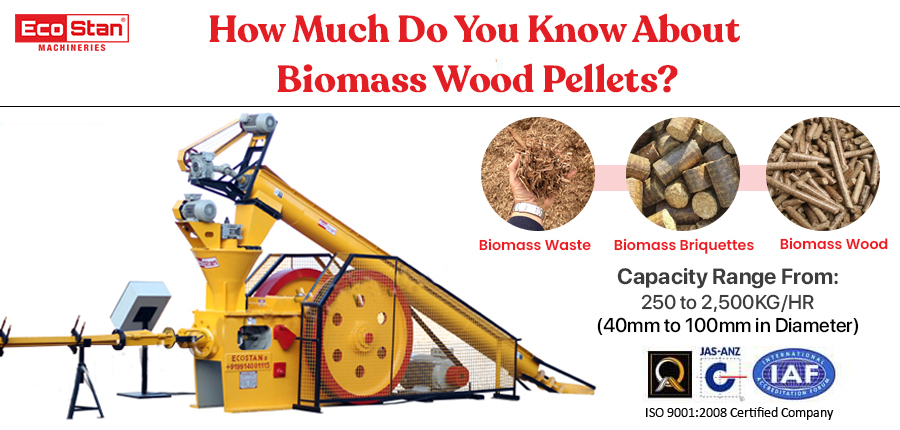

As a special strain of renewable power substitute for power generation, gasoline, and petrol, biomass fuel pellets or biomass wood pellets are becoming more widely used. The waste sawdust, shavings, and chips left over after the lumber industry are a major source of biomass wood pellet material. A pellet plant may create high-quality wood pellets through the processes of grinding, compressing, and shaping. When making firewood in the past, trees were typically chopped into sawdust and burned, generating energy that could be used for heating or boiling water. Biomass pellet machine is utilized to create pellets for warming, cooking or creature bedding. It can deal with natural substances like wood, sawdust, bamboo, pine, hay, straw, wheat grain, cotton tail, rice husk, cotton tail, and numerous other biomass materials.

Additionally, while burning firewood in a wood burning stove may look attractive, doing so is inefficient because the wood may be wet and not provide enough heat for the entire house. Additionally, once the wood is burned, a lot of ash is produced, which must be cleaned up. Our natural resources are also depleted by the felling of trees and the burning of wooden logs. On the other hand, wood pellets, which are also known as “wood fuel pellets,” are a manufactured product made when the biomass materials are crushed into a pellet shape while being subjected to high heat and pressure.

Utilization of biomass wood pellets overall:

Numerous nations regularly use biomass pellets to give nuclear power to home warming. Wood pellets, which have turned into a pillar of the energy area in Europe, have expanded in ubiquity in the US as of late, particularly in districts that utilization biomass pellet machine for sale. This is on the grounds that individuals as of now figure out the significance of feasible improvement for the climate and the economy. Wood pellets are a genuinely feasible choice contrasted with other fuel sources. Wood biomass pellets consume cleaner than coal, settling on them a superior decision for power age when ecological worries are considered.

By the measurements, in excess of a million homes in the US right now use wood pellet ovens for warming. Helpful and generally accessible, biomass wood pellets are provided on a limited scale and usually in stowed structure. Progressively now, processing plants, lodging edifices, and places of business, particularly in Europe, are utilizing biomass wood pellets to give heat for a bigger scope. Coal-discharged electric plants in Europe have started consolidating biomass wood pellets in their creation cycle due to the public authority commands for contamination and ozone harming substance outflows guideline.

Instructions for making wood pellets from biomass at home:

Since individuals can make their own wood pellets at home, pellet stoves, whether used for home heating or as part of a household, are currently more attractive than at any time in recent memory. Making wood pellets is a little more advanced than cutting squid, but with a little information on how best to make your own and the right tools, it’s easy. The first step in making your own wood pellets is obtaining the raw materials. These can be wood waste or wide variety of inexhaustible resources and various types of biomass. The material must be broken into pieces small enough to be sprayed through the holes of the granulator. The wood pellet machine packs the raw materials under high pressure and high temperature, so the biomass raw materials must be dried first to reduce their moisture content. For the best quality pellets, your material should be about 15 degrees.

For some materials, it will be necessary to add stabilizers such as vegetable oil to stick the tablets. However, with many softwood materials, such as pine and wood, they have enough specialists to glue the pellets together. The high thickness of the finished wood pellets is beneficial for efficient curing, lifting and storage. The Pellet stove fluctuates in price and can cost a lot, but it makes sense to buy wood pellets, a small amount can make a big difference and shorten the payback period. Pellet stoves are not difficult to stack and are making more sense every day, so you should check with nearby suppliers to see what is available and how much it will cost to install and run. Creating your own biomass pellets can be classified as a green energy fuel source because it is a carbon free energy source. Carbon is consumed throughout the life cycle of the tree, or natural crop, and then saved again when the pellets are lost.

The benefits of Biomass wood pellets:

There are following advantages of biomass pellet machine.

- Perfect and green:

Biomass wood pellets as another sustainable energy option with coal and gaseous fuels. When placed in the air, no substance or glue is added during the process of creating the reaction, and the carbon dioxide can be used for plant photosynthesis.

- High combustion efficiency:

Has low moisture content, it is not difficult to change the ignition air, and biomass wood pellets can be easily burned with just a piece of paper; Ultimately, the ignition efficiency is based on 80%, and the consumption intensity of many wood biomass pellets is equivalent to 0.8 batches of charcoal.

- Transport and absorption capacity:

Using the pressing method, biomass wood pellets can be easily filled and transported, saving a lot of space and money.

- Security is in use:

Biomass Wood Pellets are sourced from new wood and straw from normal cultivation and the synthetic compounds have been removed so they won’t cause damage, bumps or holes.

- Maintenance:

Once wood pellets are discarded, the waste can be used as fertilizer to promote plant growth. This is an important step in understanding the potential uses of the asset.

Conclusion:

Biomass is an intricate normal inexhaustible material with huge synthetic fluctuation. Its true capacity for energy creation shifts corresponding to the interaction utilized, which might include rudimentary or exceptionally modern innovations.